Product Introduction

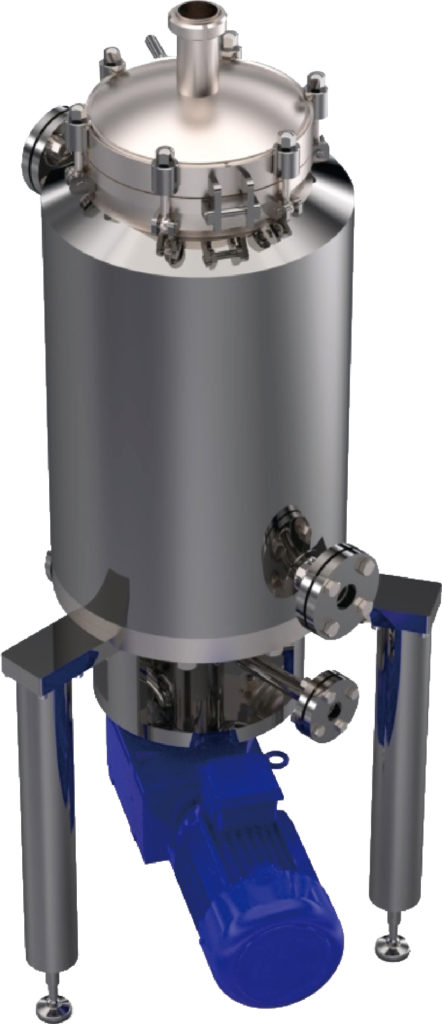

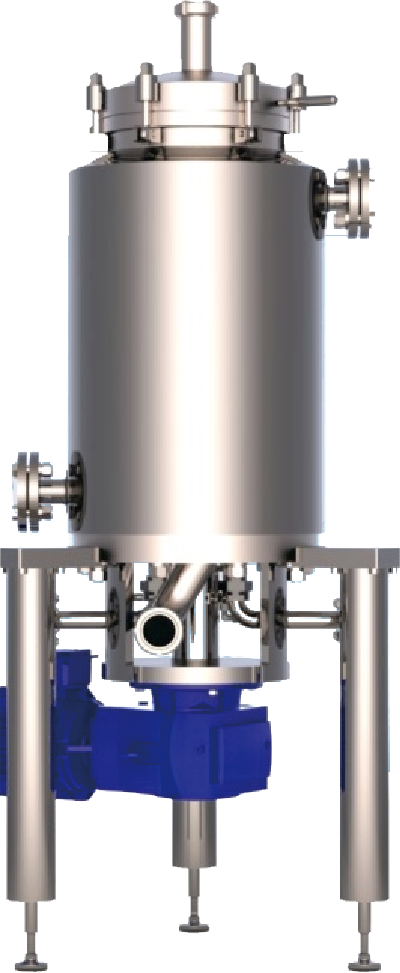

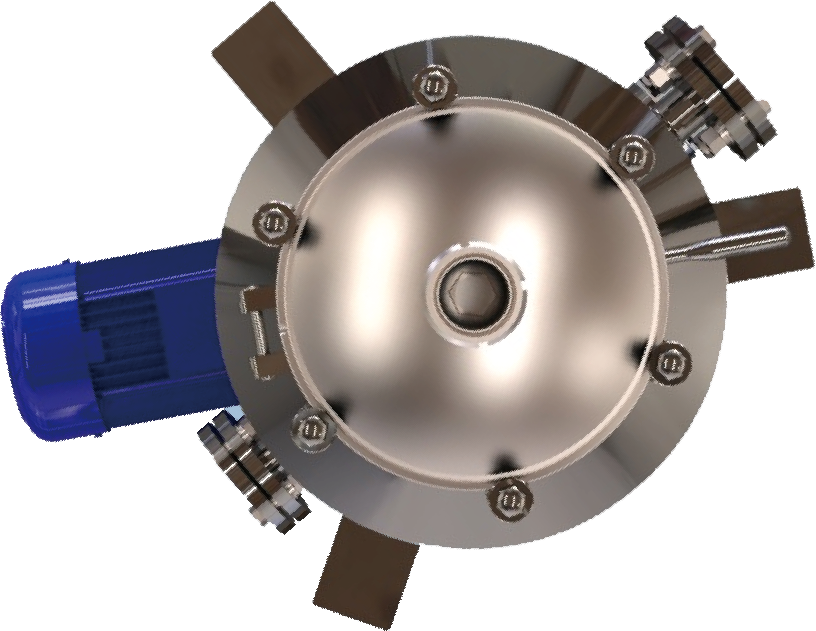

The Innohx TW series scraped surface heat exchanger is a vertical

double jacket structure, with an outer insulation layer and heating or

cooling media passing through the inner and outer jacket layers. The

product is fed from the bottom of the heat exchanger and discharged

from the top. The bottom motor drives the scraper cage to rotate, and

multiple scrapers scrape the product off the inner and outer cylinder

walls. This ensures that heat sensitive materials, high viscosity materials, high solid content materials, and materials containing large particles will not be affected by heating and cooling processes, improving mass and heat transfer efficiency, avoiding wall sticking and particle damage, and fully realizing continuous heating or cooling processes, ensuring high quality and consistency of the final product.

Application

Salad dressing, mayonnaise, tomato sauce, chickpea sauce, garlic paste, ready to eat sauce, paste, sauce, jam, fruit products, soup, cream, yogurt, concentrated dairy products, baby food, peanut butter, mashed potatoes, caramel, honey, pet food, cosmetics, cream, shower gel, Vaseline, lubricants, silicone oil, etc

Process

| Heating | Cooling | Aseptic cooling | Crystallization |

| Sterilization | Pasteurization | Gelation | Evaporation |

Features

- High heat transfer efficiency

- Vertical structure, compact design, small footprint

- Tangential feeding, gentle product handling

- Simple structure and easy to maintain

- Hygienic design, capable of CIP and SIP

- The cylinder can be made of various materials

- Standard single mechanical seal, optional double mechanical seal

- Elastomer available: silicone, FFKM, EPDM, HNBR, FKM, etc.

Design

Including scraper and scraper holder, seal, top cover, bolts, feet and other accessories, in the design and selec-tion have been considered from the following aspects: sturdy and durable, gentle handling of the product, hygien-ic design and no cleaning dead corners, easy to disassem-ble, easy to operate, ergonomic design, aesthetics, etc.

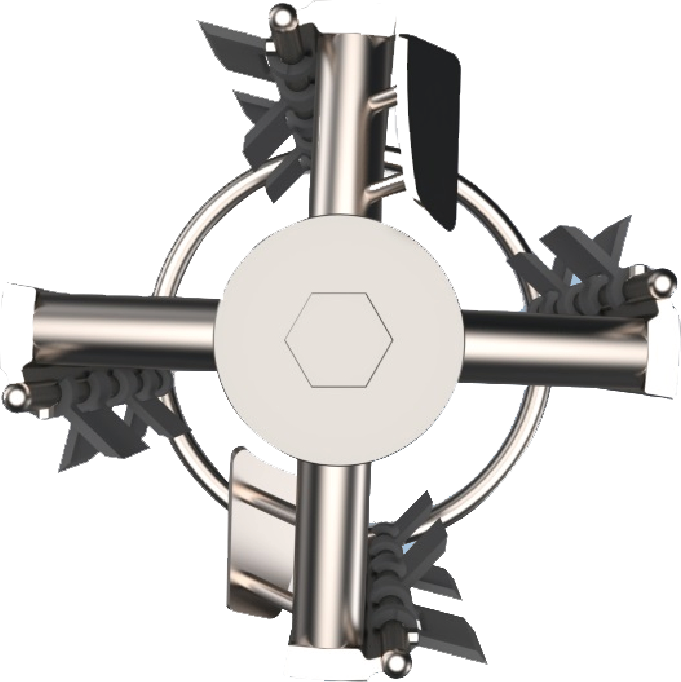

Continuous scraping of the scrapers

- Efficient heat transfer

- Does not scorch the product

- Vertical structure, small footprint

- No dirt on the surface

- Low pressure drop

Low shear

- 30-150rpm

- Low product shear and no damage to even granular materials

- Particles can be processed up to 25 mm in diameter

Scraper

- PEEK material

- Food grade, tasteless, nontoxic

- High temperature resistance

- High chemical resistance, metal detectable material

CIP/SIP

- During production, feed from the bottom and discharge from the top

- During CIP cleaning, feed from the top and discharge from the bottom

- Model TW 015 and below, cleaning flow rate 15-25 m3/h

- Model TW 020 and above, cleaning flow rate 35-45 m3/h

Cylinder material

| Material | Application |

|---|---|

| 316L | General food applications |

| 2205/31803 | Moderate corrosion application |

| SMO254/2507 | Highly corrosive applications |

Specifications & Model

The Innohx TW series scraped surface heat exchanger models range from 0.5 m2 to 7.0 m2, with a production capacity of 50 kg/h to 10,000 kg/h per unit. Our application engineers will calculate which model is suitable for your product and process based on your process parame-ters, and ultimately it may be one machine or multiple machines in series or parallel.

| Model | Heat exchange area (㎡) | Leg height (m) | Total height (m) |

|---|---|---|---|

| TW 005 | 0.5 | 0.8 | 1.3 |

| TW 010 | 1.0 | 0.8 | 1.6 |

| TW 015 | 1.5 | 0.8 | 1.9 |

| TW 020 | 2.0 | 0.8 | 2.3 |

| TW 045 | 4.5 | 1.3 | 2.4 |

| TW 070 | 7.0 | 1.3 | 3.4 |